Faster product launch, as process development and scale-up can be significantly accelerated.

Trial runs and subsequent serial production can be operated on the same system. The material consumption for process development is significantly reduced.

Saving time, space and costs.

The innovation and cost pressure in the industry is constantly increasing. As a result, more and more OSD dosage forms are being produced in Continuous Manufacturing processes. Compared to batch systems, continuous systems are significantly more space-efficient. The continuous material flow does not require any storage space for intermediate products and enables batch sizes to be scaled solely over the running time of the systems. In principle, the following applies: the leaner the design of the overall system, the easier and more precise the control over the production process. Fette Compacting therefore relies on the most compact and efficient process: direct compression.

Direct compression

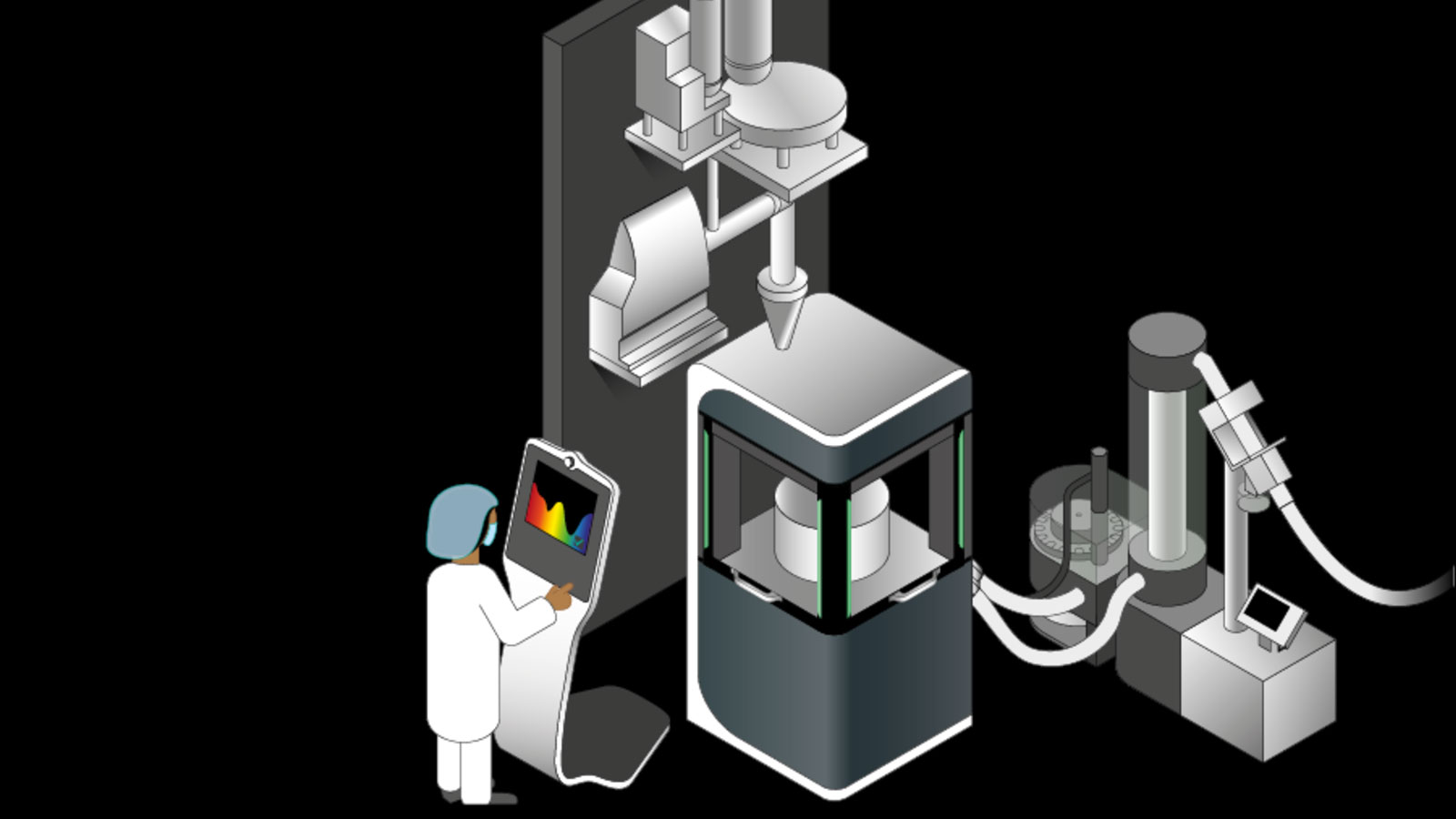

Fette Compacting relies on the highly efficient direct compression process for continuous tableting systems. After dosing, the powder is fed directly from the mixer into the tablet press without additional granulation. Compared to other continuous processes, several costly and complex production steps can be omitted. Since the short, three-step production process requires only small equipment, it takes up very little space. Direct compression offers a lot of flexibility and enables quick product changes. It also provides a guarantee of quality: by feeding the powder from the mixer directly into the tablet press in a continuous flow, factors that might reduce quality can be minimized.

Direct compression

The space-saving and efficient quality guarantee.

Service

A test system for direct compression is available in the Competence Center in Schwarzenbek. The production line includes an FE Series tablet press, a mixing system and up to seven dosing units. It offers:

- Feasibility studies

- Evaluation of individual components (dispenser, mixer, tablet press, PAT, etc.)

- Improving of Continuous Manufacturing-know-how and special process knowledge

Service

Our process experts examine the processability of specific formulations and support the entire development phase.

FE CPS – the gamechanger

For real-time analysis of powder and tablet quality using the PAT (Process Analytical Technology) system, Fette Compacting primarily relies on Near-Infrared Spectroscopy (NIR). A NIR sensor in the tablet press allows each individual tablet to be examined for the concentration of active ingredients and to optimize the production process based on the data obtained. NIR spectroscopy is a particularly fast measuring method and therefore ideally suited for high-performance machines. When the NIR sensors reach their limits, Fette Compacting uses Raman spectroscopy. Thanks to a powerful laser, this method can often be used to precisely determine even low concentrations of substances.

FE CPS – the gamechanger

Lean plant design. Short process time. Fast product changeovers. Continuous manufacturing has never been easier, more cost-efficient and more flexible.

What is and will

continue to be important.

Articles and reports on current developments and technological innovations. For even more efficiency!

Want to know more about Continuous Manufacturing?

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.

Global Sales

Fette Compacting GmbH

Grabauer Str. 24

21493 Schwarzenbek

Germany