Highlights of the Series.

The P Series is distinguished by cost orientation with precision, quality and safety. It complies with all of the requirements in accordance with cGMP and FDA. Easy and flexible production, fast format change.

Perfect combination of efficiency and quality

Combining cost-orientation with precision, quality and safety was the guiding principle during development of the P Series.

Electronic control

Equipped with an advanced VME bus. Top-class controls and electrics. Software designed in-house by Fette Compacting.

Suitable for all batches.

From small to very large batches. The P Series offers the right machine for cost-efficient and ultra-precise operations in any production capacity.

P1010

The most compact machine in the P Series. Easy cleaning and fast turret change.

DownloadStations

32

max.

Tablet output

230,400

max. per h

Tablet size

25 mm

max.

Dimensions and Weight

| Height | Width | Depth | Weight |

| 1,888 mm | 1,163 mm | 900 mm | approx. 2,000 kg |

P2020

Ideal for medium-sized volumes. Maximum standards in terms of productivity, precision and operational safety.

DownloadStations

47

max.

Tablet output

338,400

max. per h

Tablet size

25 mm

max.

Dimensions and Weight

| Height | Width | Depth | Weight |

| 2,010 mm | 1,450 mm | 1,200 mm | approx. 3,600 kg |

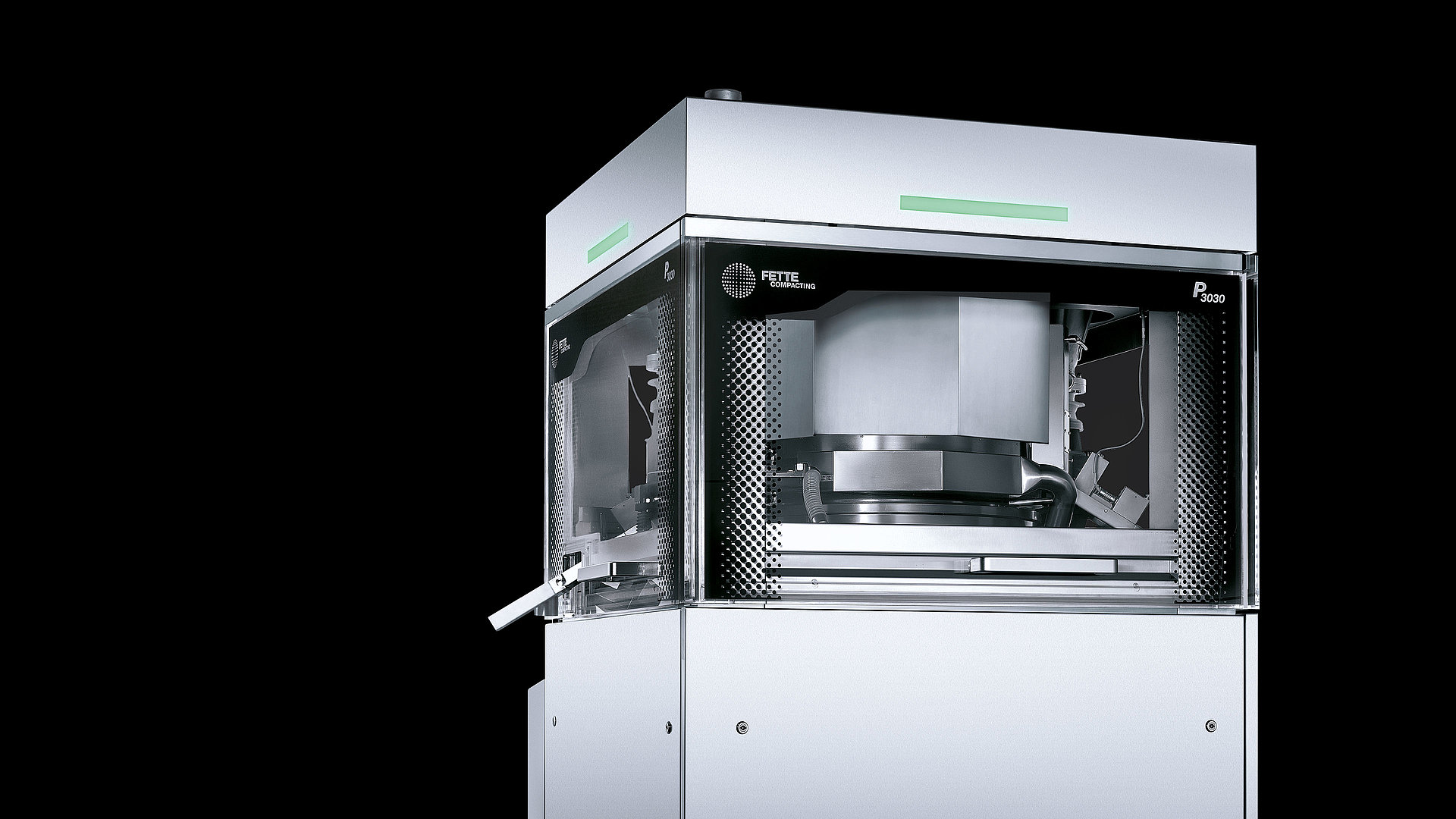

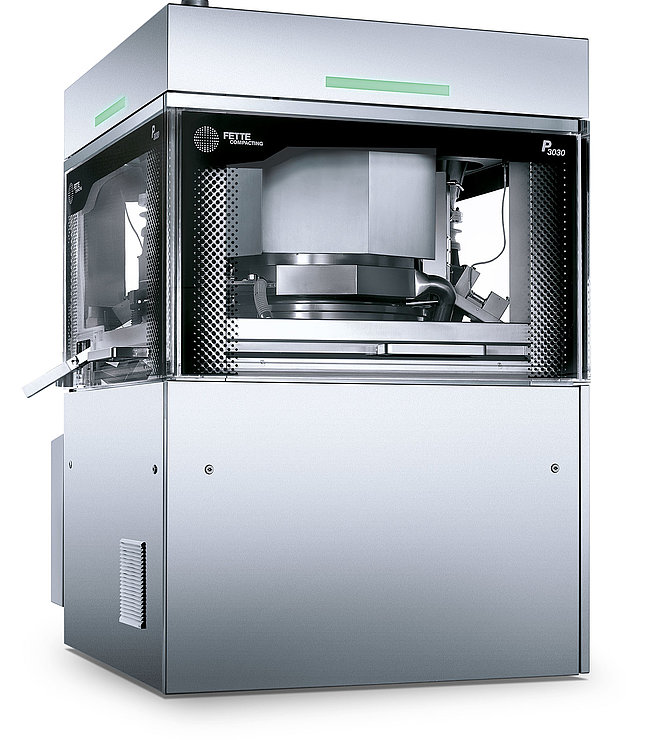

P3030

For large batches of single- and double-layer tablets offering outstanding value for money.

DownloadStations

79

max.

Tablet output

1,004,880

max. per h

Tablet size

25 mm

max.

Dimensions and Weight

| Height | Width | Depth | Weight |

| 2,073 mm | 1,620 mm | 1,370 mm | approx. 4,800 kg |

What is and will

continue to be important.

Articles and reports on current developments and technological innovations. For even more efficiency!

Want to know more about the P Series?

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.

Global Sales

Fette Compacting GmbH

Grabauer Str. 24

21493 Schwarzenbek

Germany