The automated analysis enables formulation developments to be optimized in a resource-saving manner.

Based in northern Germany, MAGNESIA GmbH distributes high-quality minerals for solid formulation products. The specialist uses the F Lab powder analyzing unit for a product development - with multiple possibilities.

For more than 40 years, MAGNESIA has been supplying mineral raw materials for manufacturers of nutrition supplements, food, pharmaceuticals and cosmetics, as well as for users of technical applications. Using Fette Compacting’s F Lab Powder Compaction Analyzing Unit (PCA unit), the company has carried out extensive data analyses for a new product for the first time.

Versatile analysis device

The F Lab is suitable for a wide variety of applications: from feasibility studies through quality control to troubleshooting during ongoing production. As an analyzing device, it can be used to examine formulations in terms of their compaction process. Users can test raw materials under special conditions and compare various formulations with each other. The compact unit even detects variations in the mineral mixture, for example due to a change in composition. Accordingly, it offers some decisive advantages during the process of developing new products.

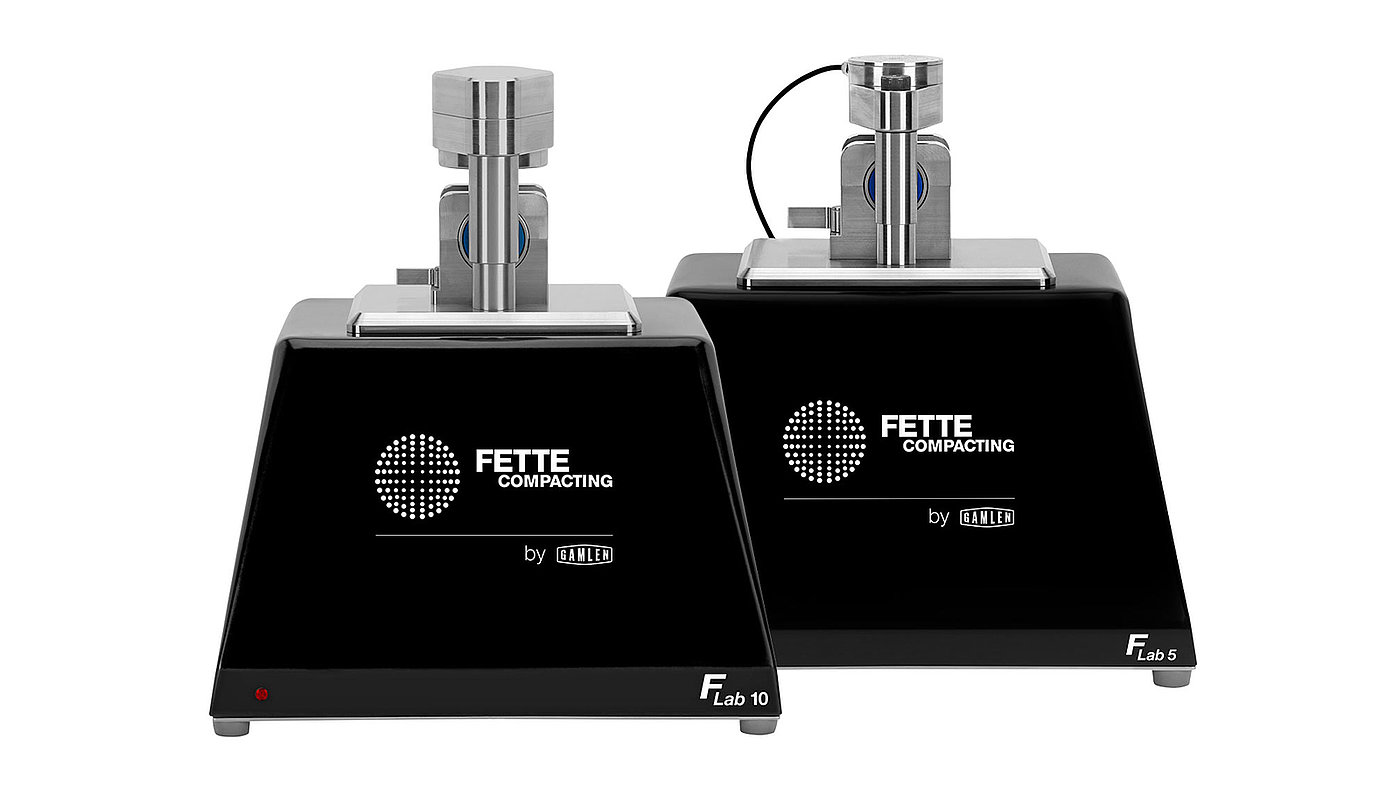

The analyzing unit works fully automatically and is available in two versions: the F Lab 5 has a pressing force of up to five kilonewtons and is suitable for tablets up to ten millimeters in diameter while the F Lab 10 manages up to 10 kilonewtons for tablets up to 15 millimeters. The associated program for automatic data evaluation and presentation can be combined with other analyzing devices according to customer requirements.

Data analysis in practice

The analysis process couldn’t be easier: the operator weighs the powder required for the tablet, fills the die, and starts the process via the computer program. It records the tablet properties such as thickness, mass, diameter and hardness. During the measurement, the program calculates a variety of parameters: ejection force, breaking strength, elastic recovery, and more. Via automatic visualization with graphs, even less specialized personnel can clearly see which powder mixtures have the best tableting properties.

Customers benefit from easy handling as operators can be swiftly trained on the device. Automated analysis of the compacting process means that formulation developments can be optimized at an early stage and in a resource-saving manner. This leads to shorter scale-up and times-to-market, better understanding of the product, and the avoidance of production errors. The F Lab also saves on resources as comparatively little powder is required for the tests. If a formulation needs revising, the F Lab is capable of detecting this before resources have been integrated in production. Apart from the lower material costs, this also ensures shorter downtimes by production machinery. Users can also use the device in parallel with the ongoing process for troubleshooting. With the F Lab PCA unit and other laboratory equipment MAGNESIA investigates new formulations in the simplest way imaginable.The automated analysis enables formulation developments to be optimized in a resourcesaving manner.

In operation at MAGNESIA

For MAGNESIA, the question was which of four different mineral granulates of the same raw material is best suited for tableting. Within this scope, it was also necessary to identify possible weak points of the different granulates and to test different parameter settings, such as compression force.

The extensive and in-depth analysis with the F Lab enabled MAGNESIA to make the right, data-based decisions in product development. The tool was able to show graphically which granulates would work best under which parameters and properties in mass production.

A trial at Fette Compacting in Schwarzenbek now also enables MAGNESIA to compare raw material qualities and suppliers in a cost-efficient manner. When defects occur, the F Lab users can quickly rule out the possibility that they originate from their own product. This is a decisive factor in long-term quality assurance. In addition, the F Lab extends its knowledge about the company’s own products and their properties. This is a major advantage when talking to customers.

F Lab Series: first understand, then produce

Quality by Design (QbD) states that high-quality products can only be manufactured with a sufficient understanding of products and processes. The F Lab characterizes the compaction behavior of powders down to the last detail. This knowledge can be used throughout the product life cycle – from development to quality control.